**Switch off equipment at the power source when not in use** – this simple action could slash your facility’s energy consumption by up to 40%. De-energized equipment refers to machinery, tools, and systems completely disconnected from their power supply during idle periods, eliminating phantom energy drain that costs Australian businesses an estimated $860 million annually.

**Conduct an equipment audit across your facility** to identify machines left in standby mode overnight, on weekends, or between production runs. Manufacturing plants, warehouses, and commercial kitchens typically discover dozens of opportunities where conveyors, compressors, lighting systems, and HVAC units consume power unnecessarily.

**Implement isolation procedures** by installing readily accessible isolation switches, training staff to power down equipment during breaks, and creating visual reminders near machinery. Melbourne-based packaging manufacturer Greenway Solutions reduced their electricity bills by 32% within six months simply by de-energizing their production line outside operating hours – a change that required minimal investment but substantial operational discipline.

**Establish de-energization protocols** that balance safety requirements with energy savings. Beyond the financial benefits, this practice extends equipment lifespan by reducing unnecessary wear on components and dramatically decreases workplace electrical hazards. For facilities operating under ISO 14001 environmental management standards, systematic de-energization demonstrates measurable commitment to sustainability.

The opportunity is particularly significant for Australian businesses facing rising energy costs and ambitious emissions reduction targets. With commercial electricity prices climbing 18% over the past three years, de-energizing idle equipment transforms from best practice to competitive necessity. This straightforward strategy delivers immediate returns while contributing to Australia’s pathway toward net-zero emissions by 2050.

What De-Energized Equipment Actually Means (And Why It Matters)

When most Australian businesses think they’ve powered down equipment at the end of a shift, there’s often more going on than meets the eye. Understanding what truly “de-energized” means can unlock significant energy savings and boost your facility’s sustainability credentials.

Here’s the reality: switching off unused appliances isn’t always the same as de-energizing them. Think of it like the difference between pressing pause on your favourite streaming show versus completely shutting down your TV. Industrial equipment operates across several distinct states, each consuming varying amounts of energy.

**Active equipment** runs at full capacity, performing its intended function—whether that’s powering production lines, running HVAC systems, or operating manufacturing machinery. **Idle equipment** remains on but isn’t actively working, like a computer left running overnight. This state still draws substantial power while producing nothing.

Then there’s **standby mode**, perhaps the most misunderstood state. Equipment in standby maintains power to components like control panels, heating elements, or monitoring systems. A Melbourne manufacturing facility recently discovered their “switched off” injection moulding machines were consuming 15% of their full operating power while supposedly offline—costing thousands annually.

**Truly de-energized equipment** means complete electrical isolation from the power source. No phantom loads, no standby consumption, zero energy draw. This is achieved through isolation switches, disconnecting circuits, or physically unplugging equipment.

The common misconception? Many assume flipping a switch or pressing a button achieves complete shutdown. In reality, numerous industrial systems maintain “vampire power” consumption—keeping sensors active, preserving memory functions, or maintaining temperature controls. These seemingly small draws accumulate across facilities, contributing to Australia’s industrial sector consuming over 100,000 gigawatt-hours annually.

Understanding these distinctions empowers businesses to identify genuine energy-saving opportunities. When equipment truly isn’t needed, complete de-energization becomes a powerful strategy for reducing both operational costs and environmental impact.

The Real Cost of Equipment That Never Truly Rests

The Energy Drain You Can’t See

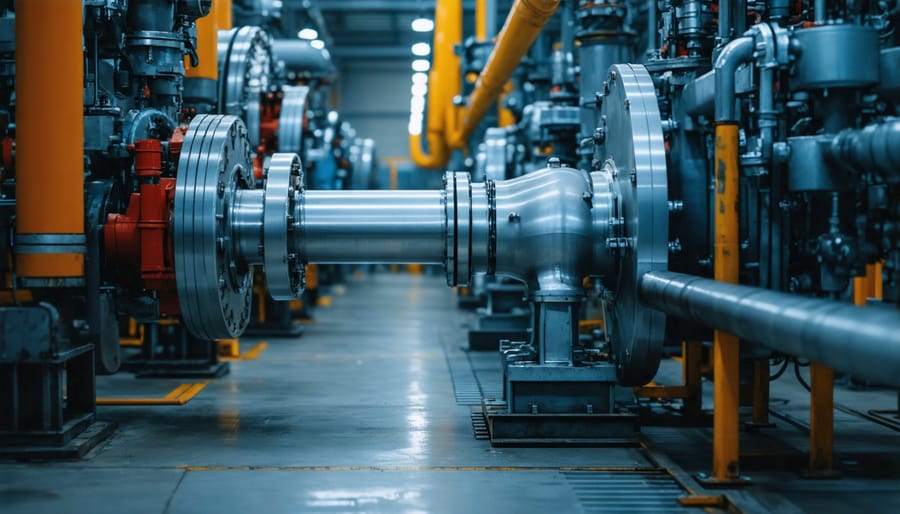

Picture this: across Australia, countless motors, pumps, and processing lines sit idle during off-peak hours, quietly drawing power like a tap left running. This hidden energy drain costs Australian businesses millions annually and contributes unnecessarily to our carbon footprint.

At wastewater treatment facilities throughout Queensland and Victoria, pumps that could be temporarily powered down during low-flow periods often remain energised 24/7, consuming up to 15-20% more electricity than necessary. That’s roughly equivalent to leaving 50 household refrigerators running constantly—purely to maintain equipment in standby mode.

Manufacturing plants face similar challenges. A medium-sized facility in Melbourne’s west discovered that idle machinery was responsible for nearly 30% of their total energy consumption during non-production hours. To put this in perspective, that’s comparable to powering an entire suburban street for a year—completely wasted.

Food processing operations tell a similar story. Between production runs, conveyor systems, refrigeration units, and processing equipment often remain powered when they needn’t be. An abattoir in regional New South Wales reduced their energy bills by 18% simply by implementing proper de-energisation protocols during downtime.

The reality is that many facilities operate under the “always on” mindset, believing equipment needs constant power for quick restarts. However, this approach drains both resources and budgets unnecessarily. Understanding where your energy actually goes is the crucial first step toward meaningful change.

What It’s Costing Your Bottom Line

Let’s talk numbers, because understanding the real cost of idle equipment might surprise you. Across Australia, businesses are unknowingly hemorrhaging money through equipment left energized during downtime—and with our energy prices among the highest globally, every watt counts.

Consider a typical medium-sized manufacturing facility running motors, compressors, and HVAC systems. Even in standby mode, a 15kW motor draws approximately 2-3kW of parasitic load. At current Australian commercial electricity rates averaging $0.35 per kWh, that single motor costs roughly $6,132 annually when left energized unnecessarily during non-production hours.

Now multiply that across your facility. A small operation with just five pieces of equipment sitting idle overnight and weekends could be spending $15,000-$30,000 yearly on absolutely nothing. For SMEs operating on tight margins, that’s money that could fund sustainability initiatives, staff training, or equipment upgrades.

The Australian Energy Market Operator reports that commercial facilities typically waste 15-30% of their energy consumption on de-energized equipment. For a business spending $100,000 annually on electricity, that translates to $15,000-$30,000 literally powering empty space. The opportunity here isn’t just about cost savings—it’s about redirecting resources toward growing your business while reducing your environmental footprint.

The Carbon Footprint of ‘Doing Nothing’

Picture this: across Australia, thousands of pieces of industrial equipment sit quietly humming in standby mode right now—compressors, conveyor systems, lighting, and machinery consuming electricity while producing absolutely nothing. It’s the industrial equivalent of leaving every light on in an empty house, 24/7.

This “doing nothing” energy consumption accounts for up to 15% of industrial electricity use nationwide, contributing millions of tonnes of greenhouse gas emissions annually. For context, that’s comparable to the emissions from hundreds of thousands of cars on our roads each year. As Australia works toward our commitment of net zero emissions by 2050, tackling idle equipment energy waste represents one of the most straightforward opportunities available.

The good news? Unlike many environmental challenges, this one has an immediate solution. De-energizing equipment when it’s not in use doesn’t require groundbreaking technology or massive investment—just awareness and action from our business community.

Which Equipment in Your Facility Is Secretly Wasting Energy

You might be surprised to learn that your facility is likely paying for energy consumption around the clock—even during off-peak hours when equipment should be idle. Across Australian industrial and wastewater treatment facilities, this silent energy drain is more common than you’d think, quietly inflating operational costs and environmental footprints.

**Pumps and Motors: The Always-On Culprits**

Standby pumps are particularly notorious energy wasters. Many facilities maintain backup pumps in a “ready” state, with motors consuming power even when not actively moving water. A typical 15kW standby pump left energized can waste approximately $2,400 annually in electricity costs—multiply that across multiple pumps, and the figures become staggering. Similarly, conveyor motors and agitators often remain powered during maintenance windows or production downtime, drawing substantial parasitic loads.

**Control Systems Working Overtime**

Your facility’s control panels, PLCs (Programmable Logic Controllers), and SCADA systems require power to function—but do they need to run at full capacity 24/7? Many Australian wastewater treatment plants discovered that keeping entire control cabinets energized during planned shutdowns was costing them thousands annually. Even in standby mode, these systems draw considerable phantom loads that accumulate over time.

**HVAC Systems Running Empty**

Climate control systems represent another significant opportunity. Equipment rooms and control buildings often maintain full heating or cooling even when facilities operate on skeleton crews or during shutdowns. One Melbourne-based industrial plant found their HVAC systems were conditioning empty spaces for 16 hours daily, representing nearly 30% of their total building energy consumption.

**Air Compressors: The Hidden Leak**

Compressed air systems rarely achieve complete shutdown. Even when production stops, compressors frequently cycle on to maintain system pressure, compensating for leaks and keeping downstream equipment pressurized. For every bar of unnecessary pressure maintained, you’re potentially wasting 7-10% of compressor energy.

**Monitoring and Instrumentation**

While essential for operations, continuous monitoring equipment—flow meters, level sensors, and analytical instruments—often remains fully powered during extended downtimes. Optimizing specialist equipment schedules can significantly reduce this consumption without compromising safety or data integrity.

The good news? Identifying these energy vampires is the first step toward meaningful savings. By understanding which equipment genuinely requires continuous power for safety and process integrity—and which can be safely de-energized—your facility can begin capturing substantial energy and cost reductions while advancing Australia’s sustainability goals.

How to Properly De-Energize Your Industrial Equipment

Creating a De-Energization Assessment

Before you can make meaningful changes, you’ll need a clear picture of what’s actually happening across your facility. Creating a thorough de-energization assessment might sound daunting, but breaking it down into manageable steps makes the process surprisingly straightforward—and often eye-opening.

Start by walking your facility during different shifts and seasons. Many Australian businesses discover equipment running overnight that hasn’t been touched in months, or air conditioning systems cooling empty warehouses through mild winter evenings. Document every piece of equipment, noting its operating schedule, power consumption (check your electrical panels or existing monitoring systems), and actual usage patterns.

Next, gather your team for honest conversations. Your maintenance crew, floor supervisors, and operational staff know which equipment truly needs to run constantly and which pieces are “just always on.” Their insights are invaluable—they’ve likely noticed inefficiencies but perhaps lacked the platform to voice concerns.

Now comes the safety-critical assessment. Some equipment absolutely must remain energized for safety systems, security, refrigeration of perishables, or continuous processes. Create a clear distinction between “mission-critical,” “operationally beneficial,” and “unnecessary” equipment. This isn’t about compromising safety or productivity—it’s about being intentional.

Document your findings in a simple spreadsheet: equipment name, location, power draw, current operating hours, proposed new schedule, and potential savings. Calculate the annual energy waste by multiplying unnecessary operating hours by power consumption. You’ll likely find that 15-30% of your energy usage could be eliminated without impacting operations—a substantial opportunity for both cost savings and environmental impact that resonates with Australia’s commitment to reaching net-zero emissions.

Safe De-Energization Procedures That Work

Safe de-energization isn’t just about flicking a switch—it’s about protecting your team and creating a culture of workplace safety. Australian facilities following AS/NZS 4836 (Safe Working on or Near Low-Voltage Electrical Installations and Equipment) understand that proper isolation procedures save lives and prevent costly accidents.

The foundation of effective de-energization starts with lockout/tagout (LOTO) protocols. Before any maintenance or shutdown period, identify all energy sources—electrical, hydraulic, pneumatic, and thermal. Your team should physically disconnect equipment from power sources, then apply individual locks and tags that clearly indicate who’s working on the system and when it’s expected back online. This simple step prevents tragic accidents from premature re-energization.

Here’s what successful Australian businesses are doing: they’ve integrated isolation procedures into their daily workflows rather than treating them as bureaucratic hurdles. After disconnecting power, verification becomes critical. Use appropriate testing devices to confirm zero energy state—don’t rely on indicator lights or meters alone. Many Victorian manufacturers now employ the “test-try-test” method: test your measuring device on a known live source, verify zero energy on your equipment, then test your device again to confirm it’s still functioning.

Documentation matters enormously. Keep detailed records of isolation points, verification results, and personnel involved. This creates accountability while building a knowledge base for future maintenance cycles. When everyone understands these procedures aren’t obstacles but safeguards protecting colleagues and community, compliance becomes second nature.

Smart Automation Makes It Easier

The good news? You don’t need to micromanage every power switch in your facility. Modern automation technology has made intelligent de-energization remarkably straightforward, allowing Australian businesses to save energy without constant manual intervention.

Programmable timers remain one of the simplest yet most effective solutions. They can automatically power down non-essential equipment during off-peak hours, weekends, or holidays—ensuring your warehouse lighting isn’t burning bright at 2 AM when nobody’s there. Many Australian manufacturers now integrate these features directly into their energy efficient equipment, making adoption even easier.

Smart power management systems take this further by learning your operational patterns and adapting accordingly. These systems can communicate across your facility network, coordinating shutdowns in logical sequences that maintain safety and readiness.

IoT sensors add another layer of intelligence, detecting actual usage patterns rather than relying on predetermined schedules. If a meeting room sits empty or a production line finishes early, sensors trigger automated de-energization—no human intervention required.

Several Australian businesses are already seeing remarkable results. A Melbourne distribution centre reduced standby power consumption by 43% using smart automation, while maintaining full operational flexibility. The system paid for itself within eighteen months through reduced electricity bills alone.

Australian Businesses Already Saving Big with De-Energization

Australian businesses are proving that de-energization isn’t just theory—it’s delivering real results right here on home soil. From Melbourne’s western suburbs to Brisbane’s industrial heartland, forward-thinking companies are slashing their energy bills while making significant environmental gains.

Take the case of Barwon Water’s wastewater treatment facility in Geelong. After conducting a comprehensive equipment audit in 2022, the utility identified 47 pieces of equipment running unnecessarily during off-peak periods. By implementing automated shutdown protocols and optimizing their operational schedules, they’ve reduced annual electricity consumption by 180,000 kWh—saving approximately $54,000 per year while cutting 135 tonnes of CO2 emissions. “We were essentially paying to run equipment that wasn’t actively treating water,” explains Operations Manager Sarah Chen. “The solution was simpler than we imagined.”

Similarly, Precision Metal Works, a mid-sized manufacturer in Western Sydney, transformed their energy profile by de-energizing idle machinery. Their maintenance team discovered that CNC machines, compressors, and conveyor systems consumed substantial standby power—sometimes up to 40% of their active running costs. By installing smart power management systems and establishing clear shutdown procedures, they’ve achieved a 28% reduction in off-peak energy use, translating to $38,000 in annual savings. They’ve since reinvested these savings into renewable energy systems, creating a powerful sustainability cycle.

Brisbane’s Logan Food Processing Plant offers another compelling example. After implementing a staged de-energization strategy across their refrigeration and processing lines, they’ve reduced their carbon footprint by 15% while maintaining full production capacity. The key lesson? Start with low-hanging fruit—equipment that’s obviously idle—before tackling more complex operational changes.

What connects these success stories is their methodical approach: audit first, prioritize opportunities, train staff thoroughly, and monitor results consistently. Each business also emphasized that engaging their teams was crucial—operators who understood the ‘why’ became champions of the initiative, suggesting improvements and ensuring protocols were followed.

These aren’t isolated victories. They’re part of a growing movement of Australian businesses recognizing that every kilowatt-hour saved strengthens both their bottom line and our shared environmental future.

Getting Started: Your First Steps Toward Energy-Optimized Equipment

Taking the first step towards de-energizing your equipment doesn’t require a complete operational overhaul. Many Australian businesses have discovered that starting small yields impressive results whilst building momentum across their organisation.

**Begin with a baseline audit.** Walk through your facility during off-peak hours—evenings, weekends, or between shifts. You’ll likely spot computers humming in empty offices, machinery idling unnecessarily, or HVAC systems running at full capacity in unused spaces. One Sydney manufacturing firm discovered 40% of their equipment remained powered during non-production hours, costing them $18,000 annually in wasted energy.

**Identify your quick wins.** Target equipment with simple power-down protocols that won’t disrupt operations. Office equipment, lighting in unused areas, and non-essential machinery are perfect starting points. Brisbane-based logistics company TransportLink began by implementing automatic shutdown timers on warehouse lighting, reducing energy consumption by 15% within the first month—without affecting a single delivery schedule.

**Address the elephant in the room:** equipment lifespan concerns. Research shows that modern equipment actually benefits from proper rest cycles. Continuous operation can accelerate wear, particularly on motors and cooling systems. Think of it like your car—occasional rest prevents overheating and extends component life. Document baseline equipment performance metrics now to demonstrate improvements later.

**Measure what matters.** Install sub-meters on key equipment zones to track energy consumption patterns. Many Australian energy providers offer free energy audits—take advantage of this resource. Just as businesses implement water conservation strategies by measuring usage, tracking energy consumption reveals hidden opportunities.

**Build your business case** by starting with a single department or equipment category. Calculate current costs, project savings, and present a three-month pilot program. When Melbourne’s Precision Parts ran their pilot, documented savings convinced leadership to roll out company-wide de-energization protocols within six months.

The key is momentum—each small success builds confidence and demonstrates that energy optimisation enhances rather than hinders operations.

De-energizing your equipment isn’t just a smart operational decision—it’s an investment in Australia’s sustainable future that pays immediate dividends. Every piece of machinery powered down when idle represents dollars saved on energy bills and a tangible reduction in your carbon footprint. For Australian businesses facing rising energy costs and increasing pressure to meet sustainability targets, this practice offers a rare win-win scenario that’s both economically sound and environmentally responsible.

The beauty of de-energization lies in its accessibility. You don’t need massive capital investment or complex technology to begin. Start tomorrow by conducting a simple walkthrough of your facility during off-peak hours. Identify equipment that’s drawing power unnecessarily—that compressor running at night, the conveyor system idling over weekends, or the lighting illuminating empty spaces. These observations form your roadmap for immediate action.

Create a shutdown checklist for your team, implement clear protocols, and train staff on the importance of switching off equipment at the end of shifts. Many Australian businesses have discovered that these straightforward measures can reduce energy consumption by 15-30% within months.

As we work collectively toward Australia’s net-zero targets, every action counts. Your decision to de-energize idle equipment ripples beyond your balance sheet—it contributes to grid stability, reduces demand during peak periods, and demonstrates leadership in sustainable business practices. Join the growing community of Australian enterprises proving that environmental responsibility and operational excellence go hand in hand. The time to act is now.